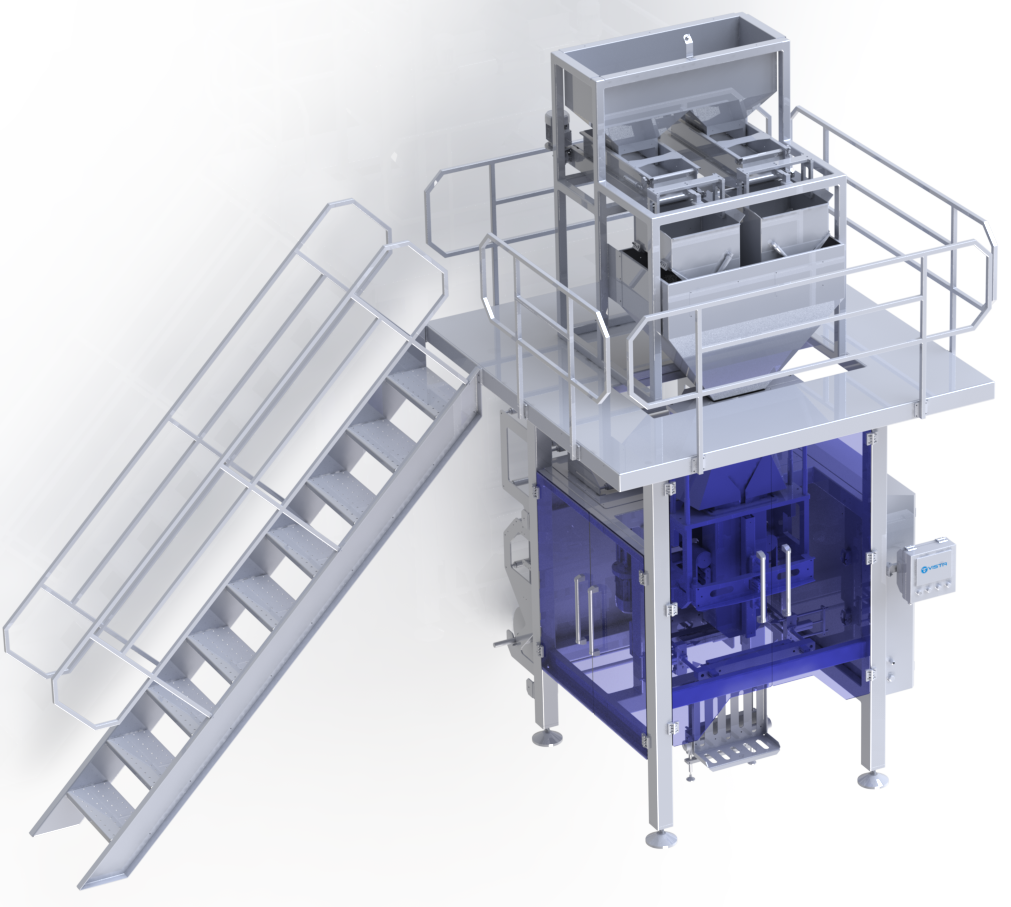

Vertical Form Fill Seal (VFFS) Machine

Vertical Form Fill Seal (VFFS) Machine

Enquiry Now

Introduction of Vertical Form Fill Seal (VFFS) Machine

Overview: VFFS machines are versatile and efficient packaging solutions designed to streamline the production of various consumer goods, from food and beverages to pharmaceuticals, cosmetics, and industrial products. They are capable of creating custom-sized bags from a continuous roll of film, filling them with product, and sealing them to ensure freshness and product integrity.

Functionality: The operation of a VFFS machine begins with the unwinding of plastic film from a roll. The film passes through a series of forming tubes where it is shaped into a tube. The tube is then sealed along its length to create a vertical pouch or bag. The bottom of the bag is sealed either by heat sealing or by a mechanical closure, depending on the type of machine and product requirements. Next, the bag is filled with the product, which can range from solids like snacks and grains to liquids such as sauces and beverages. Finally, the top of the bag is sealed, completing the packaging process.

Technical Specifications of Vertical Form Fill Seal (VFFS) Machine

-

Production Capacity: VFFS machines can typically produce between 20 to 200 bags per minute, depending on factors such as bag size, product characteristics, and machine configuration.

-

Bag Sizes: These machines can accommodate a wide range of bag sizes, from small sachets to larger bags suitable for bulk packaging.

-

Packaging Materials: They are compatible with various types of flexible packaging materials, including polyethylene (PE), polypropylene (PP), and laminates with barrier properties for extended shelf life.

Features of Vertical Form Fill Seal (VFFS) Machine

-

Versatility: Capable of packaging a diverse range of products, including dry goods, powders, liquids, and granular materials.

-

Automation: Fully automated processes reduce manual labor, increase production efficiency, and ensure consistency in packaging quality.

-

Control Systems: Equipped with advanced PLC controls and user-friendly interfaces for easy operation, monitoring, and adjustment of packaging parameters.

Benefits of Vertical Form Fill Seal (VFFS) Machine

-

-

Efficiency and Productivity:

- High-Speed Packaging: VFFS machines can achieve high production speeds, typically ranging from 20 to 200 bags per minute, depending on the product and machine configuration. This high throughput enhances productivity and meets the demands of large-scale production.

- Reduced Labor Costs: Automation reduces the need for manual intervention in the packaging process, minimizing labor costs and human error while improving efficiency.

-

Versatility and Flexibility:

- Wide Range of Products: These machines can package a variety of products, including dry goods (snacks, grains), liquids (sauces, beverages), powders, and granular materials.

- Adaptable Bag Sizes: VFFS machines can accommodate different bag sizes and shapes, from small sachets to large bags, providing flexibility in packaging options.

-

Quality and Consistency:

- Uniform Packaging: Automated processes ensure consistent filling and sealing, maintaining product integrity and presentation.

- Precision Control: Advanced control systems (such as PLCs) and sensors monitor and adjust packaging parameters in real-time, ensuring accuracy and minimizing waste.

-

Packaging Integrity and Shelf Life:

- Barrier Properties: Utilizing various plastic films (e.g., PE, PP, laminates), VFFS machines provide excellent barrier properties against moisture, oxygen, and contaminants. This helps extend the shelf life of packaged products and maintains product freshness.

- Modified Atmosphere Packaging (MAP): Some VFFS machines offer MAP capabilities, which replace the atmosphere inside the package with a protective gas mixture to further extend shelf life.

-

Cost-Effectiveness and Sustainability:

- Reduced Material Waste: Precise material handling and sealing reduce packaging material waste, contributing to sustainability goals.

- Energy Efficiency: Modern VFFS machines are designed for energy efficiency, optimizing power consumption during operation.

-

Compliance and Hygiene:

- Regulatory Compliance: VFFS machines are designed to meet industry-specific regulations and standards, ensuring compliance with food safety and product hygiene requirements.

- Clean Packaging Environment: Enclosed packaging processes minimize contamination risks, maintaining cleanliness throughout the packaging operation.

-

Applications of Vertical Form Fill Seal (VFFS) Machine

VFFS machines find extensive application across multiple industries:

-

Food Industry: Packaging of snacks, coffee, frozen foods, and confectionery.

-

Pharmaceuticals: Packaging of tablets, capsules, and medical devices in compliance with stringent hygiene and safety standards.

-

Cosmetics: Packaging of creams, lotions, and gels with precise sealing and product protection.

Conclusion

Frequently Asked Questions (FAQs)

Yes, VFFS machines are versatile and can handle liquids, powders, solids, and granules efficiently with the appropriate fillers.

Changeover time varies but is typically quick, minimizing downtime and increasing productivity.

Yes, VFFS machines can be configured for small-scale operations, offering flexibility for different production scales.

Regular maintenance includes cleaning, lubrication, and inspection of components, ensuring optimal performance and longevity of the machine.

Yes, VFFS machines can be seamlessly integrated with existing production lines, enhancing overall efficiency and output.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072