Continuous Sealer

Continuous Sealer

Enquiry Now

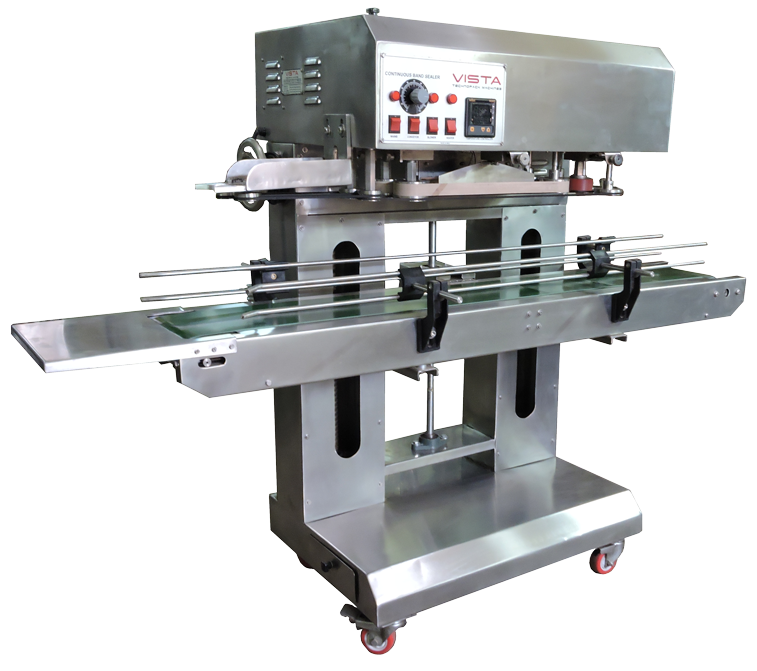

Introduction of Continuous Sealer

A continuous sealer is a crucial piece of packaging equipment used to seal the openings of flexible packaging materials like plastic bags, pouches, and film rolls. Unlike intermittent sealers that seal one package at a time, continuous sealers operate continuously, sealing packages as they move along a conveyor belt or through a sealing mechanism. These machines play a vital role across industries such as food and beverage, pharmaceuticals, cosmetics, electronics, and industrial sectors, sealing a wide array of products in flexible packaging formats. Let's explore the technical details, features, benefits, and applications of continuous sealers.

Technical Specifications of Continuous Sealer

Technical Specifications

-

Sealing Mechanism: Employs various sealing methods such as heat sealing, impulse sealing, ultrasonic sealing, or hot air sealing depending on the packaging material and product requirements.

-

Sealing Width: Offers adjustable sealing widths to accommodate different package sizes and configurations, ranging from narrow seals to wider seals.

-

Speed: Provides adjustable sealing speeds to match production requirements, with high-speed models capable of sealing hundreds of packages per minute.

-

Sealing Temperature: Allows for precise control over sealing temperature to ensure proper sealing of different types of packaging materials.

-

Sealing Pressure: Provides adjustable sealing pressure to achieve strong and reliable seals on various packaging materials and thicknesses.

-

Integration: Can be integrated with other packaging equipment such as fillers, labelers, and conveyors for a complete packaging line solution.

Features of Continuous Sealer

-

Continuous Sealing: Seals packages continuously as they move along a conveyor belt or through a sealing mechanism, maximizing packaging efficiency and throughput.

-

Adjustable Settings: Offers adjustable sealing parameters such as sealing temperature, sealing time, and sealing pressure to accommodate different packaging materials and product requirements.

-

Versatile Sealing Methods: Supports various sealing methods including heat sealing for thermoplastic materials, impulse sealing for heat-sensitive materials, ultrasonic sealing for hermetic seals, and hot air sealing for specialty films.

-

Durable Seals: Produces strong, secure, and airtight seals to protect products from moisture, contaminants, and tampering during storage and transportation.

-

Cooling System: Incorporates cooling systems or cooling bars to quickly cool and solidify the sealed area, ensuring immediate handling and further processing of sealed packages.

-

User-Friendly Interface: Features intuitive controls, touchscreen displays, and digital indicators for easy operation and monitoring of sealing parameters.

-

Safety Measures: Includes safety interlocks, emergency stop buttons, and guarding systems to prevent accidents and ensure operator safety during machine operation.

-

Compact Design: Designed with a compact footprint to optimize floor space in production facilities and accommodate various layout configurations.

Benefits of Continuous Sealer

-

-

Increased Efficiency: Automates the sealing process, reducing manual labor and human error, while increasing production output and throughput.

-

Improved Productivity: Seals packages continuously without the need for frequent starts and stops, maximizing packaging efficiency and reducing downtime.

-

Versatility: Accommodates a wide range of packaging materials and product types, providing flexibility to adapt to different packaging requirements and applications.

-

Cost Savings: Reduces labor costs, material wastage, and packaging errors, resulting in overall cost savings and improved competitiveness in the market.

-

Enhanced Product Protection: Creates strong and airtight seals to protect products from external elements, ensuring product freshness, quality, and integrity.

-

Quick Time-to-Market: Enables rapid packaging and sealing of products, allowing businesses to respond quickly to market demands and customer orders.

-

Compliance: Meets regulatory requirements and industry standards for packaging hygiene, safety, and quality, ensuring consumer satisfaction and brand trust.

-

Applications of Continuous Sealer

Continuous sealers find applications in various industries for sealing a wide range of products including:

-

Food and Beverage: Sealing of snacks, confectionery, frozen foods, pet food, coffee, tea, and condiments in flexible packaging such as pouches, bags, and sachets.

-

Pharmaceuticals: Sealing of tablets, capsules, powders, and medical devices in blister packs, pouches, and sachets for pharmaceutical and healthcare products.

-

Cosmetics and Personal Care: Sealing of skincare products, cosmetics, toiletries, and beauty products in tubes, sachets, and pouches for the cosmetic and personal care industry.

-

Electronics: Sealing of electronic components, circuit boards, cables, and wires in antistatic bags, pouches, and packaging materials for the electronics industry.

-

Industrial Products: Sealing of chemicals, lubricants, adhesives, and industrial components in bags, pouches, and packaging materials for the industrial and manufacturing sectors.

Conclusion

Frequently Asked Questions (FAQs)

A Continuous Sealer is a packaging machine used to seal the openings of filled bags or pouches. It operates continuously, allowing for high-speed sealing and increased efficiency in packaging lines.

Continuous Sealers can handle a variety of materials, including polyethylene (PE), polypropylene (PP), laminated films, and other thermoplastic materials. They are versatile and can accommodate different packaging requirements.

A Continuous Sealer works by continuously feeding bags or pouches through a heated sealing element. The heat melts the material at the opening, and pressure is applied to create a secure seal. The sealed bags are then conveyed out of the machine.

The main benefits of using a Continuous Sealer include high sealing speed, consistent seal quality, reduced labor costs, and increased production efficiency. They are also easy to operate and require minimal maintenance.

Yes, a Continuous Sealer can be used for sealing liquid products, provided the bags or pouches are designed to contain liquids and are compatible with the sealing process.

The maximum sealing width of a Continuous Sealer can vary depending on the model. However, most Continuous Sealers can handle sealing widths ranging from 5mm to 20mm.

Maintenance of a Continuous Sealer involves regular cleaning of the sealing elements, checking for wear and tear on belts and rollers, and ensuring that the heating elements are functioning correctly. It is also important to follow the manufacturer's maintenance guidelines.

Yes, a Continuous Sealer can be integrated into an existing production line. They are designed to be versatile and can be synchronized with other packaging equipment such as filling machines and conveyors.

Continuous Sealers typically include safety features such as emergency stop buttons, protective covers over hot elements, and safety interlocks to prevent accidental operation. It is important to follow safety protocols and training to ensure safe operation.

The average lifespan of a Continuous Sealer depends on the usage, maintenance, and quality of the machine. With proper care, a high-quality Continuous Sealer can last for several years, even in demanding production environments.

Yes, a Continuous Sealer can handle different bag sizes and thicknesses. Many models come with adjustable settings to accommodate various packaging requirements, ensuring a secure seal for different materials and dimensions.

While Continuous Sealers are highly versatile, they may have limitations with very thick or heavy-duty materials that require specialized sealing equipment. It is important to select the appropriate model for your specific packaging needs.

To ensure the best sealing quality, it is important to regularly inspect and maintain the machine, use compatible packaging materials, and properly adjust the sealing temperature and pressure settings based on the material being sealed. Additionally, operators should be trained to handle the machine correctly.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072