Pouch Sealer

Pouch Sealer

Enquiry Now

Introduction of Pouch Sealer

In today's competitive market, packaging plays a crucial role in preserving product quality, ensuring safety, and enhancing brand appeal. A pouch sealer is an indispensable piece of equipment in various industries, providing an efficient solution for sealing pouches and bags with precision and reliability. Pouch sealers are widely used in food, pharmaceutical, cosmetic, and chemical industries, among others, due to their versatility and ability to maintain product integrity.

Pouch sealers operate by applying heat and pressure to seal the open edges of pouches, creating a secure and airtight seal. This process is essential for protecting the contents from contamination, moisture, and external factors that could compromise product quality. The technology behind pouch sealers has evolved significantly, offering a range of models from manual to fully automated systems, catering to different production scales and requirements.

Manual pouch sealers are ideal for small-scale operations or businesses with low-volume packaging needs. These sealers are user-friendly, cost-effective, and provide reliable sealing for various pouch materials, including polyethylene, polypropylene, and laminated films. They are particularly beneficial for startups and small businesses looking to enhance their packaging processes without substantial investment.

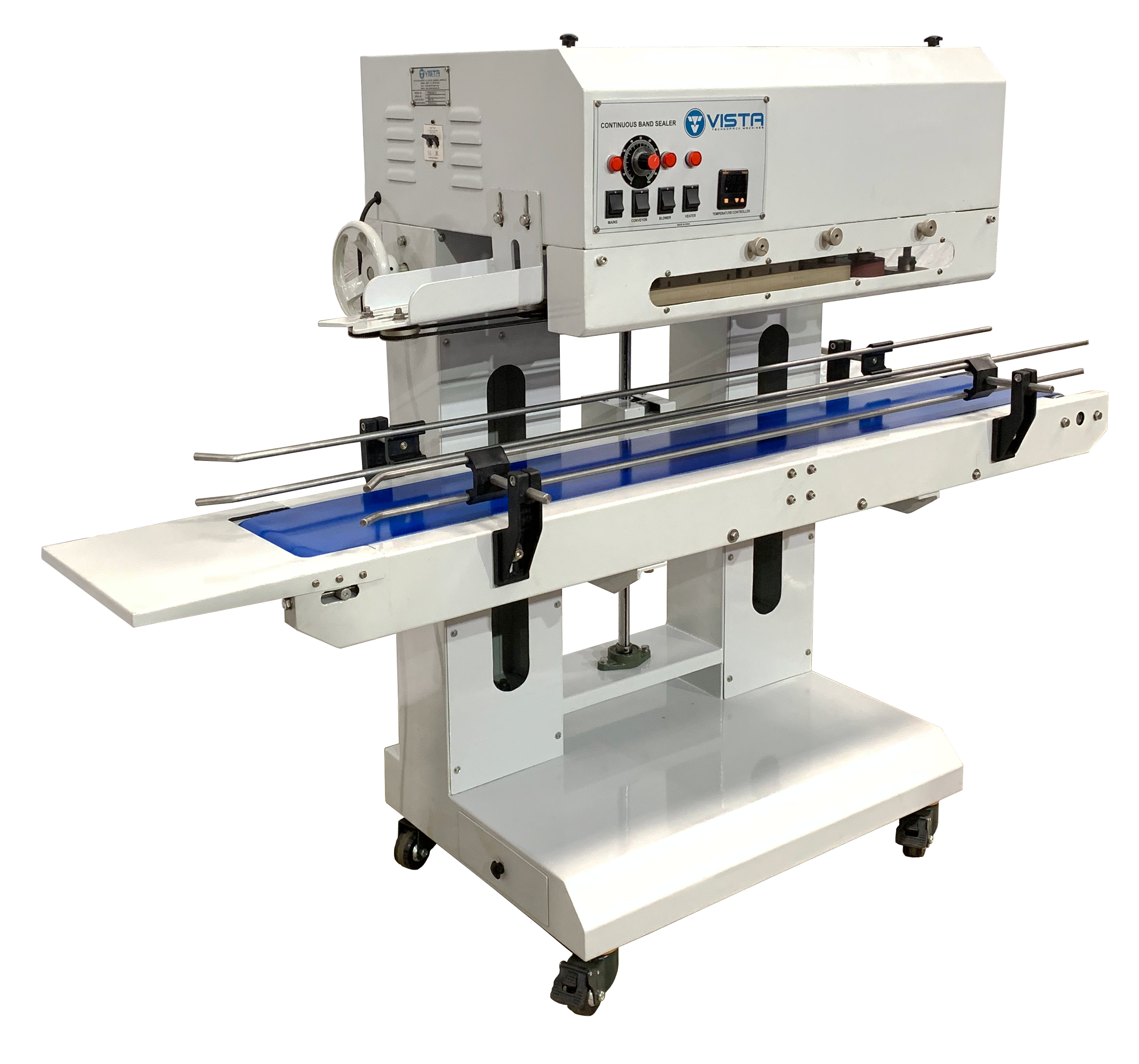

Semi-automatic and fully automatic pouch sealers are designed for medium to large-scale production environments. These machines integrate advanced features such as programmable settings, digital temperature controls, and conveyor systems, enabling high-speed and consistent sealing operations. Automation in pouch sealing not only increases production efficiency but also reduces labor costs and minimizes the risk of human error, ensuring uniform seal quality.

In the food industry, pouch sealers are crucial for packaging snacks, spices, coffee, and other perishable items, preserving freshness and extending shelf life. In the pharmaceutical sector, they ensure the safe packaging of medicines and medical devices, complying with stringent regulatory standards. Cosmetic and chemical industries also benefit from pouch sealers by securely packaging products such as creams, gels, and powders.

In summary, pouch sealers are essential tools in modern packaging processes, offering flexibility, efficiency, and reliability. Their ability to create secure seals ensures product protection and quality, making them a vital investment for businesses aiming to enhance their packaging capabilities and meet market demands.

Technical Specifications of Pouch Sealer

● Sealing Method: Heat Sealing, Impulse Sealing, Ultrasonic Sealing

● Sealing Width: Adjustable from [Range] mm

● Sealing Speed: Adjustable from [Range] meters per minute

● Seal Strength: [Range] Newtons

● Pouch Material Compatibility: Plastic, Foil, Laminated Films

● Power Supply: [Voltage] V, [Frequency] Hz

● Machine Dimensions: [Dimensions] mm

● Weight: [Weight] kg

● Application: Food Packaging, Pharmaceutical Packaging, Industrial Packaging

Features of Pouch Sealer

1. Versatile Sealing Options for Different Pouch Materials

2. Adjustable Sealing Width and Speed for Customization

3. Consistent Seal Strength for Product Safety

4. Airtight Seals for Freshness and Shelf Life Extension

5. Date Coding and Batch Printing Capabilities

6. User-Friendly Interface for Easy Operation

7. Compact Design for Space Efficiency

8. Compliance with Food Safety and Quality Standards

Benefits of Pouch Sealer

-

1. Enhanced Packaging Efficiency and Productivity

2. Improved Product Freshness and Quality Preservation

3. Customizable Sealing Options for Diverse Packaging Needs

4. Reduced Risk of Contamination and Spoilage

5. Cost-Effective Packaging Solutions

6. Branding and Information Addition on Pouches

7. Minimal Maintenance and Easy Cleaning

8. Reliable Performance for Long-Term Use

Applications of Pouch Sealer

1. Food Packaging: Snacks, Beverages, Ready-to-Eat Meals

2. Pharmaceutical Packaging: Tablets, Capsules, Powders

3. Industrial Packaging: Chemicals, Powders, Granules

4. Retail Packaging: Cosmetics, Personal Care Products

5. Medical Packaging: Sterile Instruments, Devices

6. Pet Food Packaging: Treats, Supplements

7. Agricultural Packaging: Seeds, Fertilizers

8. E-commerce Packaging: Small Items, Samples

Conclusion

Frequently Asked Questions (FAQs)

Pouch sealers can seal various materials, including plastic, foil, and laminated films, providing versatility for different packaging needs.

Pouch sealers offer sealing methods such as heat sealing, impulse sealing, and ultrasonic sealing, allowing for customizable seal strength and compatibility with different pouch materials.

Yes, many pouch sealers are designed for high-speed sealing operations, with adjustable sealing speed options to meet production requirements.

Yes, most pouch sealers feature user-friendly interfaces and minimal maintenance requirements, making them easy to operate and maintain for continuous packaging operations.

Yes, pouch sealers create airtight seals that help preserve the freshness and quality of perishable food items, extending their shelf life and reducing food waste.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072