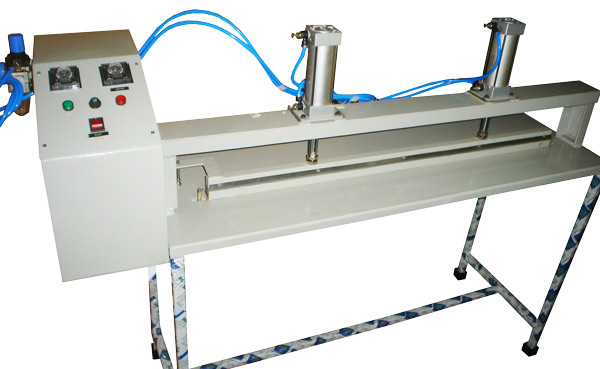

Polythene Packing Machine

Polythene Packing Machine

Enquiry Now

Introduction of Polythene Packing Machine

The polythene packing machine represents a revolution in packaging technology, offering efficient and reliable solutions for businesses across various industries. Designed to package products in polythene bags with precision and speed, this machine ensures product integrity and enhances operational efficiency.

Technical Specifications of Polythene Packing Machine

-

Packaging Capacity: Capable of sealing and packaging products in polythene bags of various sizes and thicknesses.

-

Sealing Mechanism: Utilizes heat sealing technology for secure and airtight seals.

-

Speed: Variable sealing speeds to match production requirements.

-

Material Compatibility: Suitable for sealing polyethylene (PE) and polypropylene (PP) bags.

-

Power Consumption: Energy-efficient design for cost-effective operation.

-

Dimensions: Compact footprint for space-saving installation.

-

Safety Features: Includes safety interlocks and emergency stop mechanisms for operator safety.

Features of Polythene Packing Machine

-

Versatile Sealing: Capable of sealing polythene bags of different sizes and thicknesses.

-

Adjustable Settings: Allows customization of sealing parameters such as temperature and pressure for optimal seal quality.

-

User-Friendly Interface: Intuitive controls and touchscreen displays simplify operation and setup.

-

High-Speed Operation: Designed for efficient sealing to meet production targets.

-

Robust Construction: Durable build quality ensures long-term reliability and performance.

-

Seal Quality Monitoring: Incorporates sensors and indicators to ensure consistent seal quality.

-

Easy Maintenance: Modular design and access panels facilitate quick and hassle-free maintenance procedures.

Benefits of Polythene Packing Machine

-

-

Product Protection: Ensures products are securely sealed and protected from external contaminants.

-

Operational Efficiency: Streamlines packaging operations, reducing labor costs and improving overall productivity.

-

Cost Savings: Energy-efficient operation and reduced material wastage contribute to cost savings over time.

-

Versatility: Suitable for packaging a wide range of products including food items, electronics, and industrial components.

-

Compliance with Industry Standards: Meets regulatory requirements for packaging integrity and product safety.

-

Enhanced Brand Image: Professional-looking packaging enhances product presentation and brand reputation.

-

Applications of Polythene Packing Machine

The polythene packing machine finds applications in various industries including:

-

Food and Beverage: Packages food items such as snacks, grains, and frozen foods in polythene bags.

-

Retail: Seals products for retail display and distribution in polythene bags.

-

Electronics: Protects electronic components and devices during shipping and storage.

-

Pharmaceuticals: Packages pharmaceutical products in polythene bags for distribution and storage.

-

Industrial: Seals industrial components and parts in polythene bags for transportation and storage.

Conclusion

Frequently Asked Questions (FAQs)

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072