Packaging Sealing Machine

Packaging Sealing Machine

Enquiry Now

Introduction of Packaging Sealing Machine

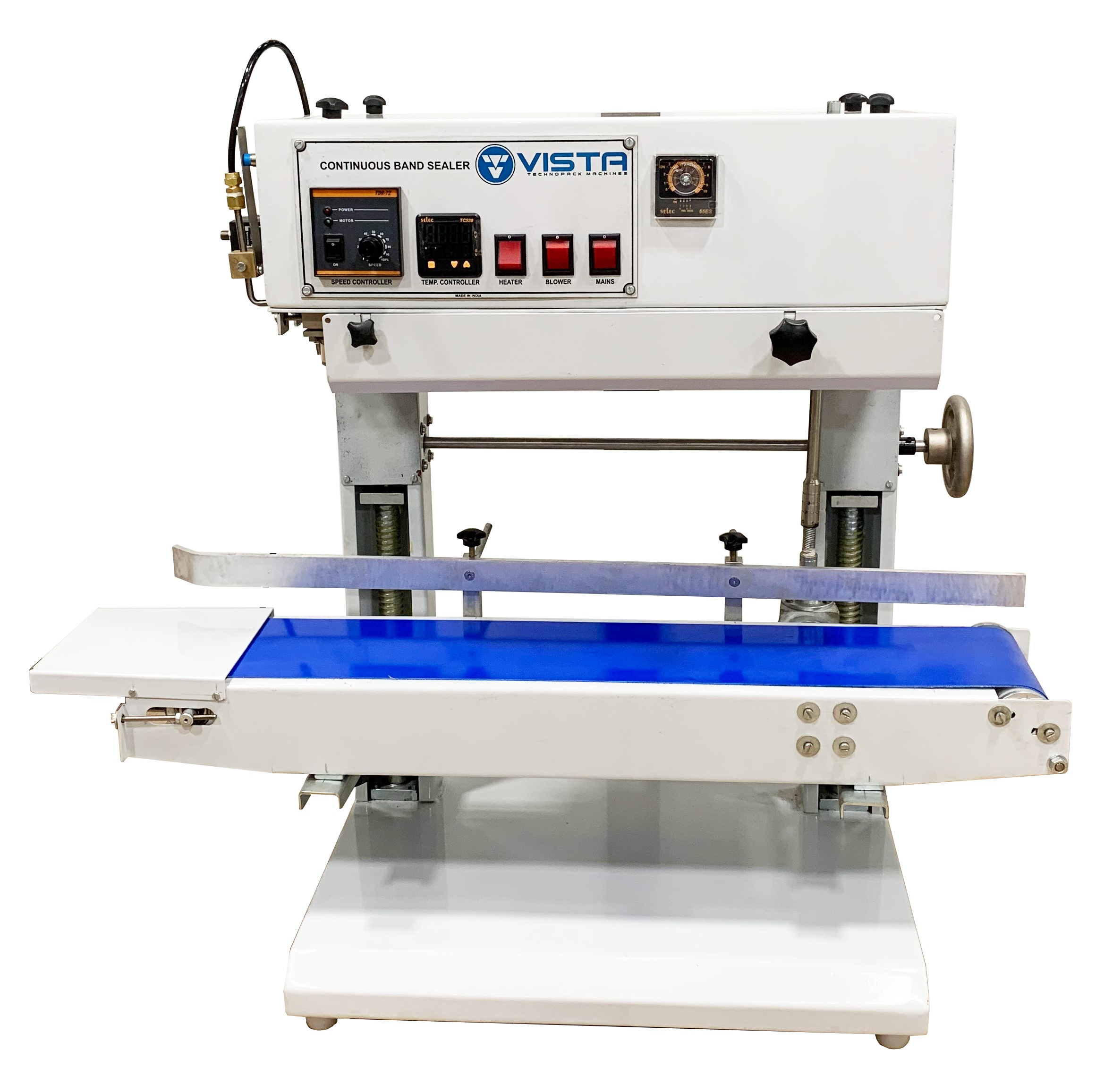

The packaging sealing machine stands as a cornerstone in modern packaging operations, offering efficient, reliable, and versatile sealing solutions for a wide range of packaging materials. This advanced machine plays a pivotal role in ensuring product protection, freshness, and integrity during storage, transportation, and display. With different types and configurations available, packaging sealing machines cater to diverse sealing needs across industries such as food and beverage, pharmaceuticals, cosmetics, and more.

The introduction of packaging sealing machines has revolutionized packaging processes by automating the sealing of various packaging materials, including bags, pouches, cartons, and containers. These machines utilize different sealing methods such as heat sealing, continuous band sealing, vacuum sealing, induction sealing, impulse sealing, and ultrasonic sealing, each tailored to specific packaging requirements.

The key features of packaging sealing machines include their versatility to handle different packaging materials, automation to reduce manual labor and increase production speeds, precision in creating strong and airtight seals, customization options to accommodate various packaging sizes and shapes, and integration capabilities with other packaging equipment for seamless operations.

Packaging sealing machines find applications across industries, sealing snacks, beverages, pharmaceutical products, cosmetics, industrial components, and more. They play a critical role in preserving product quality, extending shelf life, protecting against contamination and tampering, and enhancing product presentation.

In conclusion, the introduction of packaging sealing machines has significantly enhanced packaging efficiency, product protection, and market competitiveness for businesses worldwide. These machines continue to evolve with advanced technology and features, making them indispensable assets in the dynamic landscape of modern packaging operations.

Technical Specifications of Packaging Sealing Machine

● Sealing Method: Utilizes different sealing methods including heat sealing, ultrasonic sealing, induction sealing, and vacuum sealing, depending on the packaging material and product requirements.

● Packaging Material: Compatible with a variety of packaging materials such as plastic films, aluminum foil, laminates, and paperboard.

● Sealing Type: Offers options for various sealing types such as continuous sealing, intermittent sealing, and impulse sealing, providing flexibility for different packaging formats and production speeds.

● Sealing Width and Length: Adjustable sealing widths and lengths to accommodate different package sizes and configurations.

● Sealing Temperature: Temperature control systems to ensure proper sealing of different packaging materials and product contents.

● Sealing Pressure: Adjustable pressure settings to achieve consistent and secure seals while preventing product damage.

● Conveyor System: Equipped with conveyor belts or feeding systems to transport packages through the sealing area efficiently.

● Control System: Advanced control panels with user-friendly interfaces for precise adjustment of sealing parameters and machine operation.

Features of Packaging Sealing Machine

● Versatility: Capable of sealing a wide range of packaging materials and product types, including bags, pouches, trays, cups, bottles, and containers.

● Customization: Offers customization options for sealing parameters, allowing for tailored solutions to meet specific product and packaging requirements.

● High Efficiency: Provides fast sealing speeds and high throughput rates, maximizing productivity and reducing production lead times.

● Sealing Quality: Ensures consistent and reliable seals to maintain product freshness, prevent leakage, and protect against contamination.

● User-Friendly Design: Designed for ease of operation, with intuitive controls and ergonomic features to minimize operator fatigue and maximize efficiency.

● Space-Saving: Compact footprint to optimize floor space in production facilities and integrate seamlessly into existing packaging lines.

● Safety Features: Equipped with safety interlocks, emergency stop buttons, and guarding systems to ensure operator safety during machine operation.

● Easy Maintenance: Modular design for quick access to components, facilitating routine maintenance, cleaning, and troubleshooting.

Benefits of Packaging Sealing Machine

-

● Product Protection: Preserves product quality and extends shelf life by creating airtight and tamper-evident seals that prevent exposure to air, moisture, and contaminants.

● Increased Efficiency: Automates the sealing process, reducing labor costs, minimizing human error, and improving overall production efficiency.

● Cost Savings: Reduces packaging waste and product loss by ensuring secure seals and minimizing rework, leading to cost savings and improved profitability.

● Enhanced Product Presentation: Creates professional and visually appealing packaging that enhances brand image and consumer perception.

● Regulatory Compliance: Helps meet regulatory requirements and industry standards for packaging integrity, hygiene, and safety, ensuring consumer satisfaction and confidence.

● Market Adaptability: Adapts to changing market demands and packaging trends, allowing for quick adjustments to packaging formats, sizes, and designs.

Applications of Packaging Sealing Machine

Packaging sealing machines are used across various industries for sealing a wide range of products and packaging formats, including:

● Food Packaging: Sealing of snacks, baked goods, dairy products, frozen foods, and ready-to-eat meals in pouches, trays, and containers.

● Pharmaceutical Packaging: Sealing of medications, vitamins, and healthcare products in blister packs, bottles, and vials.

● Cosmetics Packaging: Sealing of creams, lotions, serums, and beauty products in jars, tubes, and bottles.

● Household Goods Packaging: Sealing of cleaning products, detergents, and personal care items in bottles, pouches, and containers.

● Industrial Packaging: Sealing of hardware, electronic components, and other industrial items to protect against environmental factors.

Conclusion

Frequently Asked Questions (FAQs)

A packaging sealing machine can handle various materials such as plastic films, aluminum foil, laminates, and paperboard, making it suitable for diverse packaging needs.

These machines use different sealing methods like heat sealing, ultrasonic sealing, and vacuum sealing to create airtight seals around the packaging material, ensuring product safety and integrity.

Industries such as food and beverage, pharmaceuticals, cosmetics, household goods, and industrial packaging benefit significantly from these machines due to their versatile sealing capabilities.

Yes, these machines can be integrated with other packaging equipment such as filling machines, labelers, and printers to create a complete and efficient packaging line.

Key benefits include improved product protection, increased production efficiency, cost savings, enhanced product presentation, and compliance with regulatory standards.

Yes, modern packaging sealing machines are designed with user-friendly interfaces and ergonomic features to ensure ease of operation and maintenance.

Yes, these machines offer adjustable sealing widths and lengths, allowing them to accommodate various package sizes and configurations.

They support the use of eco-friendly materials and practices, reducing packaging waste and promoting sustainable packaging solutions.

These machines come with safety interlocks, emergency stop buttons, and guarding systems to ensure operator safety during operation.

Advanced control systems and precise sealing parameters ensure that every package is sealed consistently and reliably, maintaining product quality and integrity.

A packaging sealing machine is an indispensable tool for ensuring product integrity, freshness, and safety in various industries. Its ability to provide efficient, reliable, and customizable sealing solutions makes it an essential asset for manufacturers seeking to meet the demands of today's competitive market. By investing in a packaging sealing machine, businesses can improve production efficiency, reduce packaging costs, and enhance product quality, ultimately driving growth and success in the marketplace. This investment not only optimizes packaging operations but also supports sustainability and regulatory compliance, positioning businesses for long-term success.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072