PP Bag Sealing Machine

PP Bag Sealing Machine

Enquiry Now

Introduction of PP Bag Sealing Machine

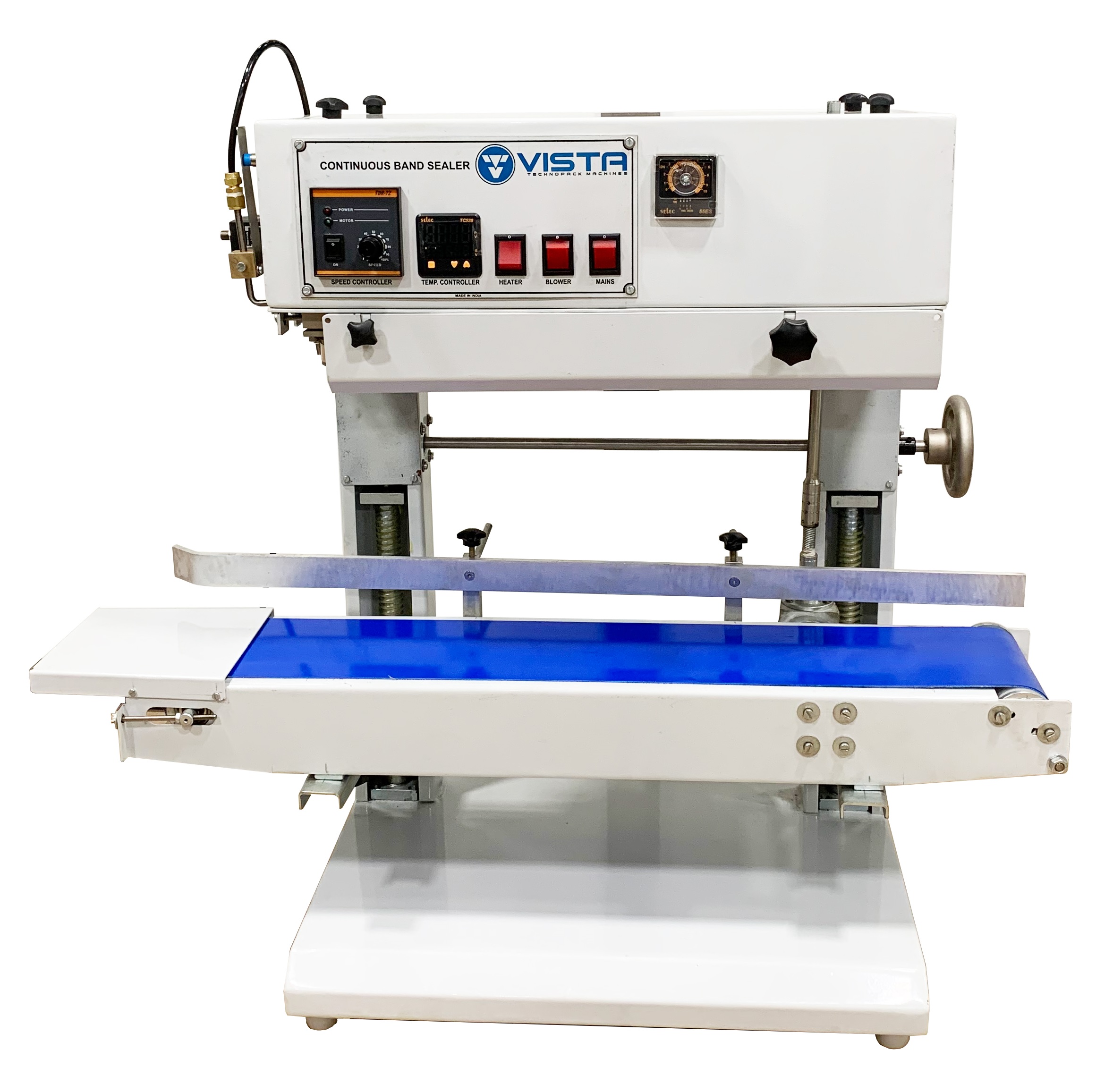

A PP (Polypropylene) Bag Sealing Machine is a critical component in modern packaging operations, designed to ensure the secure and efficient sealing of polypropylene bags used across various industries. These machines play a vital role in maintaining product integrity, enhancing shelf life, and ensuring the safety of packaged goods during storage, transport, and distribution.

Introduction to PP Bag Sealing Machine

In today's dynamic manufacturing landscape, where efficiency and reliability are paramount, PP Bag Sealing Machines stand out as indispensable tools for packaging applications. They employ advanced heat sealing technology, which applies controlled heat and pressure to effectively fuse the edges of polypropylene bags. This process creates robust, airtight seals that prevent leakage, contamination, and moisture ingress, thereby safeguarding the quality and freshness of the packaged contents.

Key Features and Capabilities:

-

Precision Sealing: PP Bag Sealing Machines offer precise control over sealing parameters such as temperature, sealing time, and pressure, ensuring consistent and secure seals across different bag sizes and types.

-

Versatility: These machines are versatile, accommodating a wide range of polypropylene bag sizes and thicknesses. They are suitable for sealing small sachets, medium-sized bags, and large bulk packaging, making them adaptable to various packaging needs.

-

Automation: Many PP Bag Sealing Machines are equipped with automated functions, including conveyor systems for efficient bag handling and sealing. Automation not only improves productivity but also reduces labor costs and minimizes human error.

-

Safety and Compliance: Ensuring operator safety is paramount in the design of these machines, with features such as safety interlocks and protective guards. They also comply with industry regulations and standards for packaging materials and processes, meeting stringent quality and safety requirements.

Applications:

PP Bag Sealing Machines find widespread application across industries including:

-

Food Industry: Sealing bags containing snacks, cereals, frozen foods, and bakery products to maintain freshness and extend shelf life.

-

Pharmaceutical Sector: Sealing bags for packaging medicines, pharmaceutical powders, and medical supplies, ensuring product safety and compliance with regulatory standards.

-

Industrial and Retail Sectors: Sealing bags used for packaging chemicals, pet products, hardware, and consumer goods, providing secure packaging for retail display and distribution.

Technical Specifications of PP Bag Sealing Machine

● Sealing Method: Heat Sealing

● Sealing Width: 5-10 mm (adjustable)

● Sealing Length: 200-800 mm (adjustable)

● Sealing Speed: 10-30 bags per minute

● Power Supply: 220V, 50Hz

● Machine Dimensions: 1000 x 600 x 1200 mm

● Weight: 100 kg

● Bag Compatibility: PP Flat Bags, Gusseted Bags, Zipper Bags

Features of PP Bag Sealing Machine

1. Adjustable Sealing Parameters for Different PP Bag Materials

2. Continuous Sealing Capability for High-Volume Production

3. User-Friendly Interface with Digital Controls

4. Heating Element with Rapid Heat-Up Time

5. Sealing Pressure Adjustment for Optimal Seal Strength

6. Safety Features such as Overheat Protection and Emergency Stop

7. Compact Design for Space Efficiency

8. Compliance with CE and RoHS Standards

Benefits of PP Bag Sealing Machine

-

1. Enhanced Sealing Quality and Product Protection

2. Increased Production Efficiency and Output

3. Reduced Labor Costs and Packaging Errors

4. Customizable Settings for Versatile Packaging Needs

5. Improved Product Shelf Life and Freshness

6. Tamper-Resistant Seals for Consumer Confidence

7. Minimal Maintenance Requirements for Long-Term Use

8. Reliable Performance in Various Packaging Environments

Applications of PP Bag Sealing Machine

1. Food Packaging: Snacks, Frozen Foods, Dry Goods

2. Agriculture: Seed Packaging, Fertilizers, Animal Feed

3. Textiles: Apparel Packaging, Fabric Bags

4. Industrial Packaging: Hardware, Tools, Parts

5. Retail Packaging: Cosmetics, Electronics, Stationery

6. Pharmaceuticals: Medical Supplies, Drug Packaging

7. E-commerce Packaging: Online Orders, Shipping Supplies

8. Contract Packaging Services: Third-Party Packaging Solutions

Conclusion

Frequently Asked Questions (FAQs)

PP bag sealing machines are specifically designed for sealing polypropylene (PP) bags. However, some models may also be compatible with sealing other materials such as polyethylene (PE) bags or laminated bags. It's essential to check the machine's specifications for compatibility with different bag materials.

The sealing speed of PP bag sealing machines typically ranges from 10 to 30 bags per minute, depending on the model and settings. Higher-speed models may be available for applications requiring faster sealing rates.

Yes, PP bag sealing machines are designed with user-friendly interfaces and straightforward controls, making them easy to operate. Routine maintenance tasks such as cleaning the sealing area and checking for wear on sealing elements are essential for optimal performance and longevity of the machine.

Yes, PP bag sealing machines are adjustable to accommodate bags of various sizes and thicknesses. Operators can adjust the sealing width, sealing length, and sealing pressure to achieve optimal seals for different PP bag types and materials.

While PP bag sealing machines are generally easy to operate, it's beneficial for operators to receive basic training on machine setup, operation, and maintenance. Training ensures safe and efficient use of the machine, minimizing errors and maximizing productivity.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072