Manual Tube Sealing Machine

Manual Tube Sealing Machine

Enquiry Now

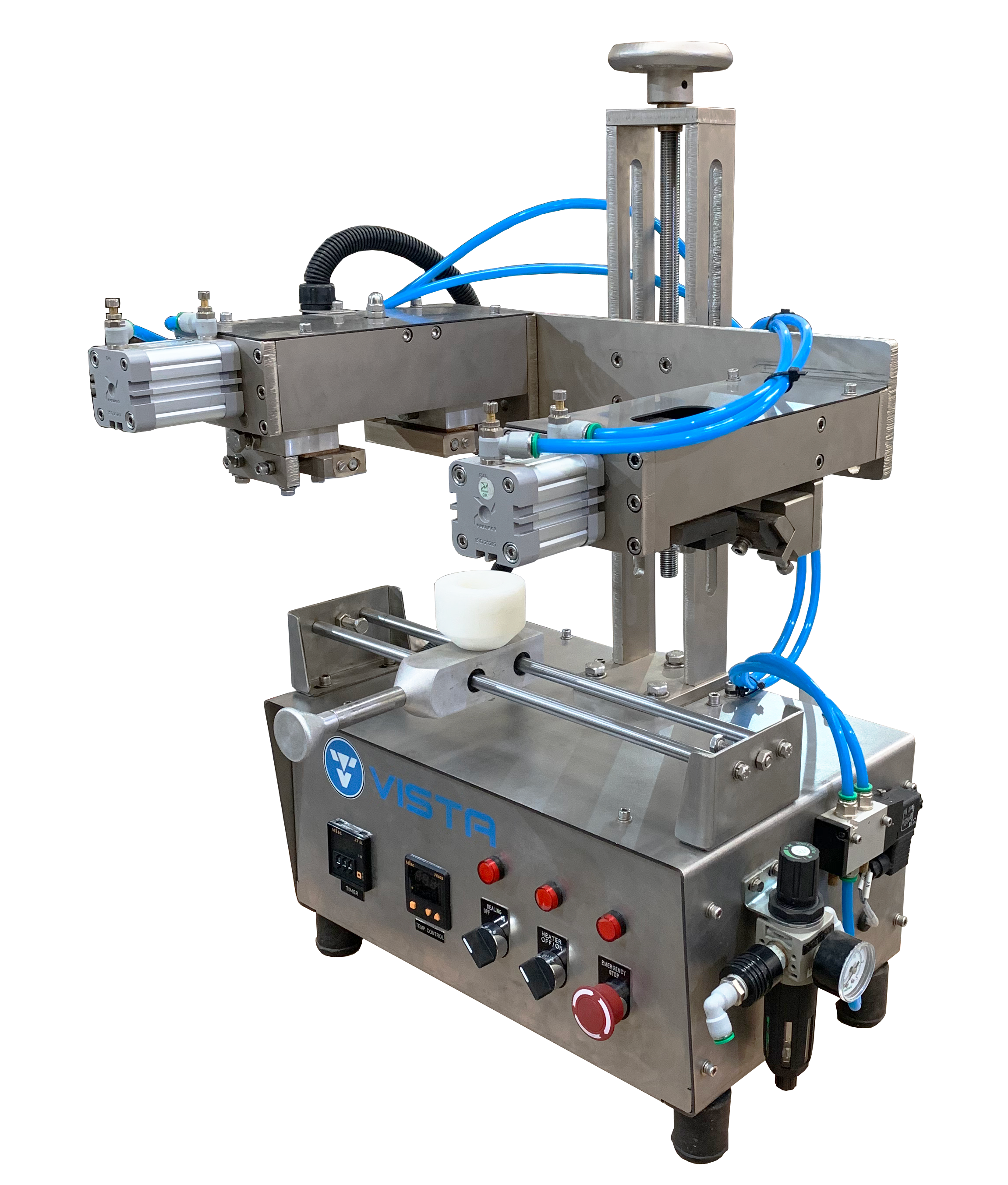

Introduction of Manual Tube Sealing Machine

In the world of packaging, maintaining product integrity and presentation is paramount, especially for products that require precise and reliable sealing. Manual Tube Sealing Machines are indispensable tools designed to meet these needs, offering a perfect blend of efficiency, flexibility, and affordability for small to medium-scale production environments. These machines are specifically crafted to seal plastic or laminate tubes filled with a variety of products, ranging from cosmetics and pharmaceuticals to food items and industrial goods.

A Manual Tube Sealing Machine operates through a simple, user-friendly mechanism that requires minimal training to master. This makes it an ideal choice for small businesses, laboratories, specialty manufacturers, and startups looking to maintain high standards of packaging without investing in expensive automated systems. The manual operation allows for precise control over the sealing process, ensuring consistent, high-quality results with each use.

The versatility of these machines is one of their standout features. They are compatible with different tube sizes and materials, allowing operators to adjust settings such as temperature and sealing time to achieve optimal results for various products. Whether sealing tubes of creams, gels, ointments, or pastes, a Manual Tube Sealing Machine provides a reliable solution that preserves the contents and extends their shelf life.

Constructed from durable materials, these machines are built to last and withstand frequent use. Their compact design makes them suitable for use in confined spaces or mobile production setups, adding to their appeal for small-scale operations. Moreover, the cost-effectiveness of manual tube sealers cannot be overstated. They represent a low initial investment while delivering high performance, making them accessible to a wide range of businesses.

In summary, a Manual Tube Sealing Machine is an essential asset for any business that values precision, quality, and efficiency in its packaging processes. Its ease of use, adaptability, and affordability make it a practical choice for ensuring that products are securely and professionally sealed, ready to reach consumers in perfect condition.

Technical Specifications of Manual Tube Sealing Machine

● Sealing Method: Heat Sealing

● Tube Diameter Range: 10 mm - 50 mm

● Sealing Temperature: Adjustable from 100°C to 200°C

● Sealing Time: Adjustable from 0.1 seconds to 3 seconds

● Power Supply: 220V, 50Hz

● Machine Dimensions: 400 x 300 x 200 mm

● Weight: 15 kg

● Tube Compatibility: Plastic Tubes, Aluminum Tubes

Features of Manual Tube Sealing Machine

1. Manual Operation for Precision Control

2. Adjustable Sealing Parameters for Versatility

3. Compact and Portable Design

4. Suitable for Various Tube Sizes and Materials

5. Durable Construction for Long-Term Use

6. Efficient Sealing Process for Product Protection

7. Cost-Effective Solution for Small-Scale Production

8. User-Friendly Interface with Control Panel

Benefits of Manual Tube Sealing Machine

-

1. Enhanced Packaging Efficiency and Accuracy

2. Customizable Sealing Parameters for Optimal Results

3. Reduced Manual Labor and Operator Fatigue

4. Compatibility with a Wide Range of Tube Types

5. Improved Product Presentation and Shelf Appeal

6. Cost-Effective Solution for Small Businesses

7. Reliable Sealing Performance for Product Integrity

8. Easy Operation and Maintenance

Applications of Manual Tube Sealing Machine

1. Cosmetics Industry: Creams, Lotions, Serums

2. Pharmaceutical Industry: Ointments, Gels, Medications

3. Chemical Industry: Adhesives, Sealants, Lubricants

4. Food Industry: Sauces, Condiments, Pastes

5. Industrial Applications: Automotive Sealants, Greases

6. Personal Care Products: Toothpaste, Hair Gels, Sunscreens

7. Arts and Crafts: Glues, Paints, DIY Products

8. Laboratory Use: Sample Tubes, Test Kits, Chemical Compounds

Conclusion

Frequently Asked Questions (FAQs)

Manual tube sealing machines are compatible with various tube materials, including plastic tubes and aluminum tubes, commonly used in industries such as cosmetics, pharmaceuticals, and chemicals.

Yes, manual tube sealing machines are equipped with adjustable sealing temperature settings, allowing operators to customize the sealing process according to the material and thickness of the tubes being sealed.

Yes, manual tube sealing machines are designed to seal tubes of different diameters, typically ranging from 10 mm to 50 mm, providing versatility for various tube sizes used in different applications.

The sealing time on a manual tube sealing machine is adjustable, typically ranging from 0.1 seconds to 3 seconds, depending on the sealing temperature and material of the tubes, ensuring optimal seal quality and efficiency.

Yes, manual tube sealing machines are cost-effective solutions suitable for small-scale production operations, offering efficient sealing capabilities, easy operation, and maintenance for businesses with lower production volumes.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072