Liner Sealing Machine

Liner Sealing Machine

Enquiry Now

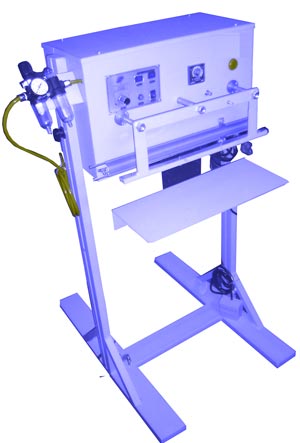

Introduction of Liner Sealing Machine

A Liner Sealing Machine is a highly specialized piece of equipment designed to enhance the packaging process by securely sealing liners within containers. These machines are integral to industries that require airtight and secure packaging solutions to protect products from contamination, preserve freshness, and ensure safety during storage and transportation. The Liner Sealing Machine automates the process of inserting and sealing liners, such as foil, plastic, or paper, into various types of containers, including jars, bottles, and drums.

In the food and beverage industry, the Liner Sealing Machine plays a crucial role in maintaining product quality by preventing exposure to moisture, air, and contaminants. It is widely used for sealing liners in containers holding sauces, spices, dairy products, beverages, and other consumables. The pharmaceutical and cosmetic industries also rely heavily on these machines to ensure the safety and integrity of products such as medicines, supplements, creams, and lotions. By providing a hermetic seal, these machines help extend shelf life and maintain the efficacy of sensitive products.

The machine operates using a combination of heat and pressure to bond the liner to the container’s opening, creating a tamper-evident and leak-proof seal. Advanced models of Liner Sealing Machines come equipped with features like programmable logic controllers (PLC) for precise control, adjustable sealing parameters to accommodate different liner materials and container sizes, and high-speed operation to meet large-scale production demands. Some machines also include automated feeding systems and inspection units to ensure consistent quality and efficiency.

With growing concerns over product safety and shelf-life extension, the demand for reliable and efficient packaging solutions like the Liner Sealing Machine is on the rise. This machine not only enhances operational efficiency but also provides peace of mind to manufacturers and consumers alike by ensuring that products reach their destinations in optimal condition. Whether for food, pharmaceuticals, cosmetics, or other industries, the Liner Sealing Machine is a vital component in modern packaging lines, underscoring its importance in today’s fast-paced manufacturing environment.

Technical Specifications of Liner Sealing Machine

● Sealing Technologies: Heat Sealing, Induction Sealing, Ultrasonic Sealing

● Sealing Width: Adjustable from 1-10 mm

● Sealing Speed: Adjustable from 20-100 seals per minute

● Seal Length: Customizable based on packaging requirements

● Power Supply: 220V, 50Hz

● Machine Dimensions: 1200 x 800 x 1500 mm

● Weight: 300 kg

● Packaging Material Compatibility: Plastic, Glass, Metal, Composite

Features of Liner Sealing Machine

1. Multiple Sealing Technologies for Versatility

2. Adjustable Sealing Parameters for Customization

3. High-Speed Sealing for Increased Productivity

4. Tamper-Evident Seals for Product Safety

5. User-Friendly Interface with Control Options

6. Compact Design for Space Efficiency

7. Compliance with Industry Standards and Regulations

8. Reliable Performance for Long-Term Use

Benefits of Liner Sealing Machine

-

1. Enhanced Packaging Efficiency and Seal Quality

2. Reduced Packaging Errors and Product Spoilage

3. Improved Product Safety and Tamper Resistance

4. Extended Shelf Life and Product Freshness

5. Cost-Effective Packaging Solutions

6. Customizable Sealing Options for Different Materials

7. Minimized Manual Labor and Operator Fatigue

8. Reliable Performance for Continuous Operations

Applications of Liner Sealing Machine

1. Food and Beverage Packaging

2. Pharmaceutical Product Packaging

3. Cosmetics and Personal Care Product Packaging

4. Chemical and Industrial Product Packaging

5. Healthcare Product Packaging

6. Pet Food and Supplies Packaging

7. Household and Cleaning Product Packaging

8. Customized Packaging Solutions for Specific Products

Conclusion

Frequently Asked Questions (FAQs)

Liner sealing machines can seal a wide range of packaging materials, including plastic, glass, metal, and composite materials, providing versatility for different packaging needs.

Liner sealing machines use advanced sealing technologies such as heat sealing, induction sealing, or ultrasonic sealing, combined with adjustable parameters and control options, to ensure consistent seal quality and integrity.

Yes, liner sealing machines are designed with adjustable sealing width and customizable seal lengths, allowing for flexibility in sealing options based on packaging requirements.

Yes, most liner sealing machines are equipped with user-friendly interfaces, control options, and accessible components for easy operation, maintenance, and troubleshooting.

Liner sealing machines are widely used in industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, healthcare, and more, where efficient and reliable sealing of packaging materials is essential.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072