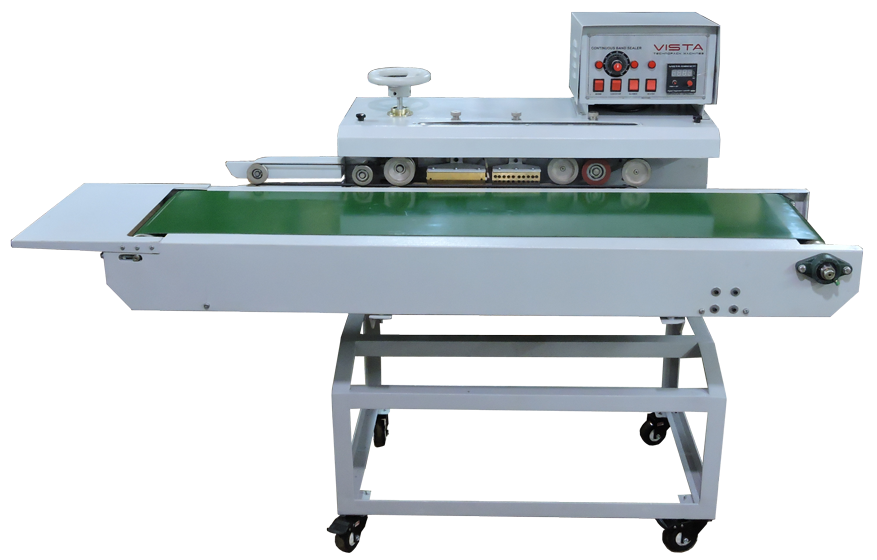

Continuous Sealing Machine

Continuous Sealing Machine

Enquiry Now

Introduction of Continuous Sealing Machine

Continuous sealing machines are integral to the packaging industry, playing a crucial role in sealing various types of packaging materials to ensure product integrity, freshness, and safety. These machines are designed to handle continuous sealing operations, making them ideal for high-volume production environments across diverse industries such as food and beverage, pharmaceuticals, cosmetics, and electronics.

Functionality and Principle: Continuous sealing machines operate on the principle of sealing packaging materials—such as plastic films, laminates, and aluminum foils—into airtight pouches or bags. They utilize heat-sealing technology to create secure seals along the edges of the packaging, preventing contamination and extending the shelf life of the enclosed products. These machines are equipped with heated sealing bars or rollers that apply controlled heat and pressure to melt and seal the packaging materials effectively.

Versatility and Adaptability: One of the key features of continuous sealing machines is their versatility. They can seal a wide range of packaging materials, including polyethylene, polypropylene, cellophane, and shrink films. This adaptability allows manufacturers to package various products, from dry foods and snacks to liquids, powders, and pharmaceuticals, in different packaging formats such as pouches, bags, and sachets.

Types of Continuous Sealing Machines: Continuous sealing machines are available in several configurations to meet specific production needs:

- Horizontal Continuous Sealer: Seals packages horizontally, suitable for larger items or products that require a wider sealing area.

- Vertical Continuous Sealer: Seals packages vertically, ideal for smaller items or products packaged in narrow bags or pouches.

- Band Sealers: Utilize conveyor belts to continuously feed and seal packages, enhancing efficiency in high-speed production lines.

Technical Specifications of Continuous Sealing Machine

● Sealing Method: Utilizes continuous heat sealing, impulse sealing, or ultrasonic sealing technology to create continuous seals along the length of packaging material.

● Sealing Width: Offers adjustable sealing widths to accommodate different bag sizes and thicknesses, ranging from narrow seals for small pouches to wider seals for larger bags.

● Sealing Speed: Provides variable speed settings to adjust sealing speed according to production requirements, ranging from a few meters per minute to tens of meters per minute.

● Packaging Material: Compatible with a wide range of packaging materials including polyethylene (PE), polypropylene (PP), laminates, aluminum foil, and paper.

● Control System: Equipped with programmable logic controllers (PLCs) and touchscreen interfaces for setting and monitoring sealing parameters such as temperature, pressure, and speed.

● Cooling System: Includes built-in cooling systems or conveyor belts to cool and solidify seals after sealing, preventing distortion or damage to the packaging material.

● Power Supply: Operates on standard electrical outlets with options for single-phase or three-phase connections.

● Material Contact Parts: Constructed from food-grade stainless steel or FDA-approved materials to ensure product safety and hygiene.

Features of Continuous Sealing Machine

● Continuous Sealing: Creates continuous seals along the length of packaging material, eliminating the need for manual repositioning or indexing between seals.

● Adjustable Sealing Parameters: Allows for precise control of sealing temperature, pressure, and speed to ensure optimal seal quality on different packaging materials.

● Automatic Temperature Control: Maintains consistent sealing temperature throughout the sealing process, preventing overheating or underheating of the sealing elements.

● Emergency Stop Function: Incorporates emergency stop buttons or safety interlocks to quickly halt machine operation in case of emergencies or safety hazards.

● Integrated Conveyor System: Includes conveyor belts or roller conveyors for automatic feeding and conveying of packaged products through the sealing zone.

● Seal Pressure Adjustment: Offers adjustable sealing pressure settings to accommodate various packaging materials and ensure proper sealing integrity.

● Printed Mark Detection: Features sensors or photocells to detect printed marks on the packaging material, allowing for accurate positioning and alignment of seals.

● Quick Changeover: Facilitates rapid changeovers between different packaging materials or product sizes with minimal downtime.

● Low Maintenance: Requires minimal maintenance with easy-to-clean surfaces and access panels for servicing and inspection.

Benefits of Continuous Sealing Machine

-

● High-Speed Operation: Increases packaging efficiency and throughput, reducing lead times and labor costs associated with manual sealing methods.

● Consistent Seal Quality: Ensures uniform and airtight seals on every package, preventing leaks, spoilage, and contamination of packaged products.

● Versatility: Accommodates various packaging materials and product types, making it suitable for diverse packaging applications in different industries.

● Cost Savings: Lowers packaging costs by minimizing material waste, product rejections, and downtime associated with poor seal quality.

● Enhanced Product Protection: Provides a protective barrier against moisture, oxygen, and external contaminants, preserving product freshness and extending shelf life.

● Compliance: Helps businesses meet regulatory requirements for food safety, hygiene, and packaging standards in various industries.

Applications of Continuous Sealing Machine

Continuous sealing machines find applications across diverse industries for sealing a wide range of products, including:

● Food Industry: Sealing of snacks, confectionery, frozen foods, dry fruits, spices, and ready-to-eat meals in pouches or bags.

● Pharmaceutical Industry: Sealing of medication pouches, blister packs, sachets, and sample collection bags containing tablets, capsules, or powders.

● Cosmetics and Personal Care: Sealing of beauty products, toiletries, creams, lotions, and hair care products in sachets or pouches.

● Chemical Industry: Sealing of chemicals, detergents, cleaning agents, lubricants, and industrial powders in packaging for distribution and storage.

Conclusion

Frequently Asked Questions (FAQs)

Continuous sealing machines can handle a wide range of materials, including polyethylene (PE), polypropylene (PP), laminates, aluminum foil, and paper, making them suitable for various packaging needs.

These machines maintain consistent sealing temperatures, pressure, and speed, ensuring uniform and airtight seals on every package, which helps in preventing leaks and contamination.

Yes, continuous sealing machines are designed for high-speed operation, with adjustable speeds to meet different production requirements, ensuring efficient and rapid sealing processes.

Safety features such as emergency stop buttons, safety interlocks, and overload protection mechanisms are integrated into these machines to ensure operator safety during operation.

Continuous sealing machines are designed for easy maintenance, with accessible parts and surfaces that are simple to clean, along with quick-change features for minimal downtime during servicing.

Absolutely, these machines are highly versatile and can be used in various industries, including food, pharmaceuticals, cosmetics, and chemicals, for sealing different types of products.

Yes, these machines offer adjustable sealing widths and quick changeover capabilities, allowing them to accommodate different bag sizes and product types efficiently.

By creating airtight and secure seals, these machines protect products from moisture, oxygen, and contaminants, thereby extending shelf life and maintaining product freshness.

These machines are equipped with programmable logic controllers (PLCs) and touchscreen interfaces that allow precise setting and monitoring of sealing parameters for optimal performance.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072