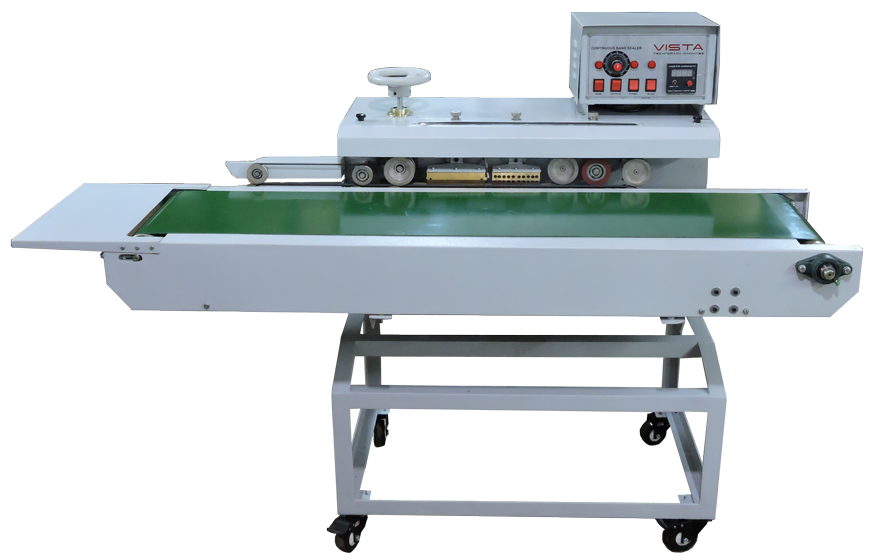

Continuous Band Sealer

Continuous Band Sealer

Enquiry Now

Introduction of Continuous Band Sealer

Continuous band sealers revolutionize packaging operations by offering consistent and efficient sealing solutions for a wide range of products. These versatile machines are engineered to handle various packaging materials, including polyethylene, polypropylene, and laminates, ensuring secure seals that maintain product freshness and integrity.

At the heart of a continuous band sealer is its conveyor system, which enables continuous sealing of packages as they move through the machine. This continuous sealing mechanism not only enhances productivity but also ensures uniformity in seal quality, reducing the risk of leaks or contamination.

One of the key advantages of continuous band sealers is their adaptability to different package sizes and shapes. Whether you're sealing pouches, bags, or cartons, these sealers can be adjusted to accommodate varying dimensions, making them suitable for diverse industries such as food and beverage, pharmaceuticals, cosmetics, and more.

Continuous band sealers are equipped with advanced heat sealing technology, including adjustable temperature controls and sealing speed settings. This precision control allows for optimal sealing conditions based on the packaging material and product requirements, ensuring strong, airtight seals that prolong shelf life and enhance product presentation.

Furthermore, these sealers are designed for durability and ease of maintenance, with robust construction and user-friendly interfaces. They are often equipped with safety features such as emergency stop buttons and temperature sensors to ensure operator safety and seal consistency.

In today's competitive market, efficient packaging is essential for product protection, brand integrity, and customer satisfaction. Continuous band sealers offer a reliable sealing solution that enhances packaging efficiency, reduces waste, and ultimately contributes to a seamless packaging workflow.

Stay ahead in the packaging industry with continuous band sealers that combine reliability, versatility, and precision sealing for optimal packaging performance. Explore the diverse range of continuous band sealers tailored to meet your specific packaging needs and elevate your packaging process to new heights of efficiency and quality.

Technical Specifications of Continuous Band Sealer

- Sealing Speed: Adjustable from 0 to 12 meters per minute, allowing for precise control over the sealing process.

- Sealing Width: Offers a range of 6 to 12 mm, accommodating various bag sizes and materials.

- Temperature Range: Wide temperature range from 0 to 300°C, ensuring compatibility with different packaging materials.

- Max. Conveyor Load: Robust conveyor system capable of handling loads up to 3 kg, facilitating continuous sealing operations.

- Power: Energy-efficient operation with a power consumption of 500W, contributing to cost savings.

- Voltage: Compatible with standard 220V power supply at 50/60Hz, suitable for diverse operational environments.

- Machine Dimensions: Compact dimensions of 1050 x 450 x 380 mm, optimizing space utilization in production areas.

- Weight: Sturdy construction with a weight of 30 kg, providing stability during operation.

Features of Continuous Band Sealer

1. Adjustable Temperature Controls for Optimal Sealing Conditions

2. Conveyor System for Continuous Sealing

3. Robust Construction for Durability

4. User-Friendly Interface with Safety Features

5. Adaptability to Various Package Sizes and Shapes

6. Precision Sealing for Airtight Seals

7. Enhanced Product Presentation and Shelf Life

Versatility Across Industries

Benefits of Continuous Band Sealer

-

1. Improved Packaging Efficiency

2. Reduced Risk of Leaks or Contamination

3. Enhanced Product Freshness and Integrity

4. Reduced Waste in Packaging Process

5. Increased Operator Safety and Seal Consistency

6. Versatile Application Across Different Industries

7. Cost-Effective Packaging Solution

8. Optimal Shelf Life Extension for Packaged Products

Applications of Continuous Band Sealer

1. Food and Beverage Packaging

2. Pharmaceuticals and Healthcare Products

3. Cosmetics and Personal Care Items

4. Industrial and Electronic Components

5. Agricultural and Chemical Products

6. Retail and E-commerce Packaging

7. Logistics and Shipping Industry

8. Contract Packaging Services

Conclusion

Frequently Asked Questions (FAQs)

Continuous band sealers offer continuous sealing for efficient packaging operations, unlike intermittent sealers that seal individual packages. This continuous sealing mechanism enhances productivity and seal consistency.

Yes, continuous band sealers are designed to handle various packaging materials, including polyethylene, polypropylene, and laminates, ensuring secure seals for a wide range of products.

Continuous band sealers are designed for durability and ease of maintenance, with robust construction and user-friendly interfaces. Regular maintenance and cleaning ensure optimal performance and longevity of the machine.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072