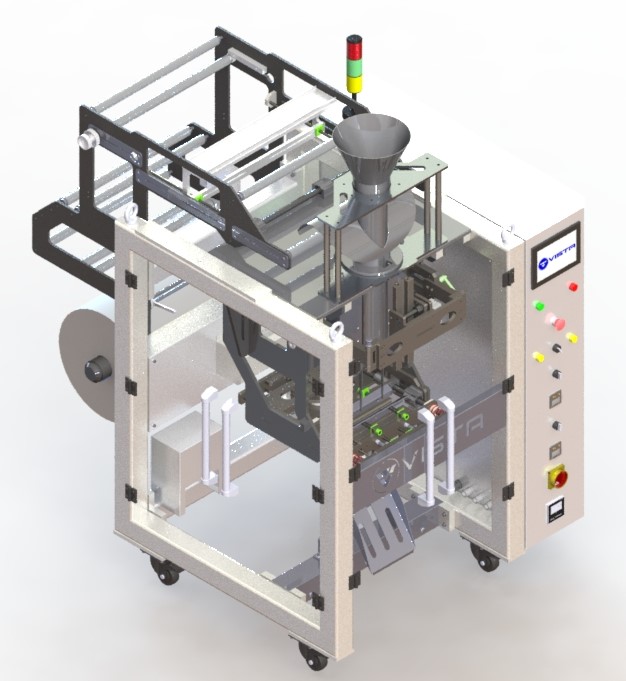

Automatic Plastic Packing Machine

Automatic Plastic Packing Machine

Enquiry Now

Introduction of Automatic Plastic Packing Machine

An Automatic Plastic Packing Machine represents a pinnacle of technological advancement in the field of packaging automation. Designed to streamline and optimize the packaging process, these machines are integral to modern industrial operations across various sectors. They automate the entire packaging workflow, from material feeding to sealing, labeling, and sometimes even palletizing, offering significant advantages in terms of efficiency, consistency, and product integrity.

In today's competitive market landscape, the demand for efficient, high-quality packaging solutions has driven the development of Automatic Plastic Packing Machines. These machines cater to diverse industries such as food and beverage, pharmaceuticals, cosmetics, electronics, and consumer goods, addressing the need for precise and reliable packaging of products.

Key Features and Capabilities:

-

Automated Operation: Automatic Plastic Packing Machines eliminate the need for manual intervention in most stages of the packaging process. They are equipped with advanced sensors, robotic arms, and programmable logic controllers (PLCs) that ensure precise control over every aspect of packaging.

-

Versatility in Packaging: These machines can handle a wide range of packaging formats, including pouches, bags, bottles, trays, and containers, using various types of plastic films and materials. They accommodate different product sizes, shapes, and packaging requirements with ease.

-

High-Speed Performance: Capable of operating at high speeds, Automatic Plastic Packing Machines significantly enhance production throughput. They optimize efficiency and reduce labor costs by automating repetitive tasks that would otherwise require significant manpower.

-

Advanced Technology Integration: Many modern machines incorporate features such as touch-screen interfaces, remote monitoring capabilities, and integration with Industry 4.0 standards. This enables real-time data analysis, predictive maintenance, and seamless connectivity with other production systems.

-

Quality Assurance and Compliance: Automatic Plastic Packing Machines ensure consistent packaging quality, adhering to stringent regulatory standards and industry-specific requirements. They employ advanced sealing technologies to maintain product freshness, hygiene, and shelf life.

Technical Specifications of Automatic Plastic Packing Machine

● Packaging Formats: Bags, Pouches, Bottles, Containers

● Filling Mechanism: Volumetric, Weighing, Auger Filling

● Fill Volume Range: 10 ml to 5000 ml (adjustable)

● Speed: Adjustable from 20 to 120 packs per minute

● Sealing Methods: Heat Sealing, Ultrasonic Sealing

● Power Supply: 220V, 50/60Hz

● Machine Dimensions: 1500 x 1200 x 1800 mm

● Weight: 600 kg

● Material Compatibility: PE, PP, PVC, Multi-layer Films

Features of Automatic Plastic Packing Machine

1. High-speed operation for increased productivity

2. Precision filling and sealing for consistent quality

3. Customizable packaging formats and sizes

4. User-friendly control panel with touchscreen interface

5. Robust construction for durability and low maintenance

6. Automated adjustments for various packaging materials

7. Integrated labeling and coding options

8. Compliance with industry standards and safety regulations

Benefits of Automatic Plastic Packing Machine

-

1. Enhanced production efficiency and output

2. Consistent product quality and reduced wastage

3. Versatile packaging solutions for different industries

4. Reduced labor costs and manual intervention

5. Improved packaging aesthetics and shelf appeal

6. Compliance with food safety and quality standards

7. Long-term reliability and operational efficiency

8. Cost-effective packaging solutions

Applications of Automatic Plastic Packing Machine

1. Food and Beverage Packaging (snacks, sauces, beverages)

2. Pharmaceutical Packaging (pills, syrups, ointments)

3. Cosmetic Packaging (creams, lotions, shampoos)

4. Consumer Goods Packaging (detergents, cleaning products)

5. Industrial Products Packaging (lubricants, chemicals)

6. Contract Packaging Services

7. Retail and Wholesale Packaging

8. Customized Packaging Solutions

Conclusion

Frequently Asked Questions (FAQs)

Automatic plastic packing machines can package a wide range of products including food items, beverages, pharmaceuticals, cosmetics, consumer goods, and industrial products.

These machines support various packaging formats such as bags, pouches, bottles, and containers, providing versatility for different product types and sizes.

Automatic plastic packing machines use precise filling mechanisms like volumetric filling, weighing, and auger filling, combined with advanced control systems to ensure accurate and consistent fill levels.

Yes, automatic plastic packing machines can be configured with different sealing methods such as heat sealing and ultrasonic sealing, depending on the packaging material and product requirements.

Yes, most automatic plastic packing machines are designed with user-friendly control panels and robust construction, making them easy to operate and maintain with minimal downtime.

Other Products

Our company is built on innovation, success, and satisfied customers. We believe that packaging is an essential component of any product, and it is our goal to provide our clients with customised wrapping options.

Products

- - Plastic Heat Sealing Machine

- - Semi-Automatic Cup Filling Sealing Machine

- - Lubricant Filling Machine

- - Paste Packing Machine

- - Namkeen Chips Packing Machine

- - Mixture Packing Machine

- - Mini Flow Pack Machine

- - Honey Pouch Packing Machine

- - Collar Type Packing Machine

- - Round Bottle Labeling Machine

Quick Contacts

If you have any questions or need help

- +91 99878 77751

17/B, Sultan Market, A. G. Link Road, Near BMC School, Sakinaka, Andheri East, Mumbai, Maharashtra 400072